FPSO P-76

Start of work

Paraná, Brazil

We built and assembled the modules of one of the largest offshore projects ever carried out in Brazil.

workers at peak construction

engineering labor hours

tons in total

FPSO P-76

Brazilian suppliers were involved in the project

local content

million hours of construction

million contract amount

Brazilian suppliers were involved in the project

local content

million hours of construction

million contract amount

Flare Tower

Flare Tower

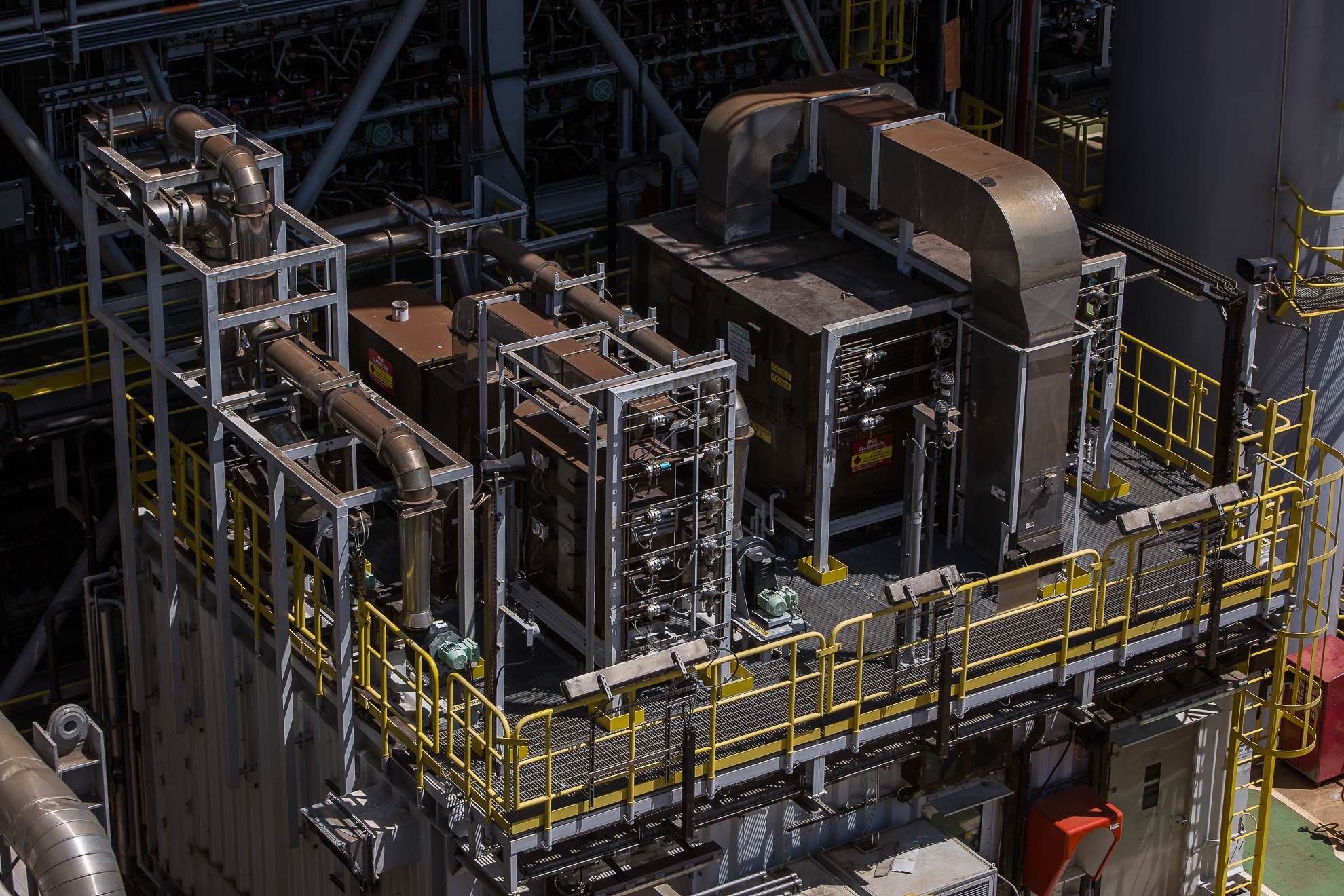

Energy generation

Energy generation

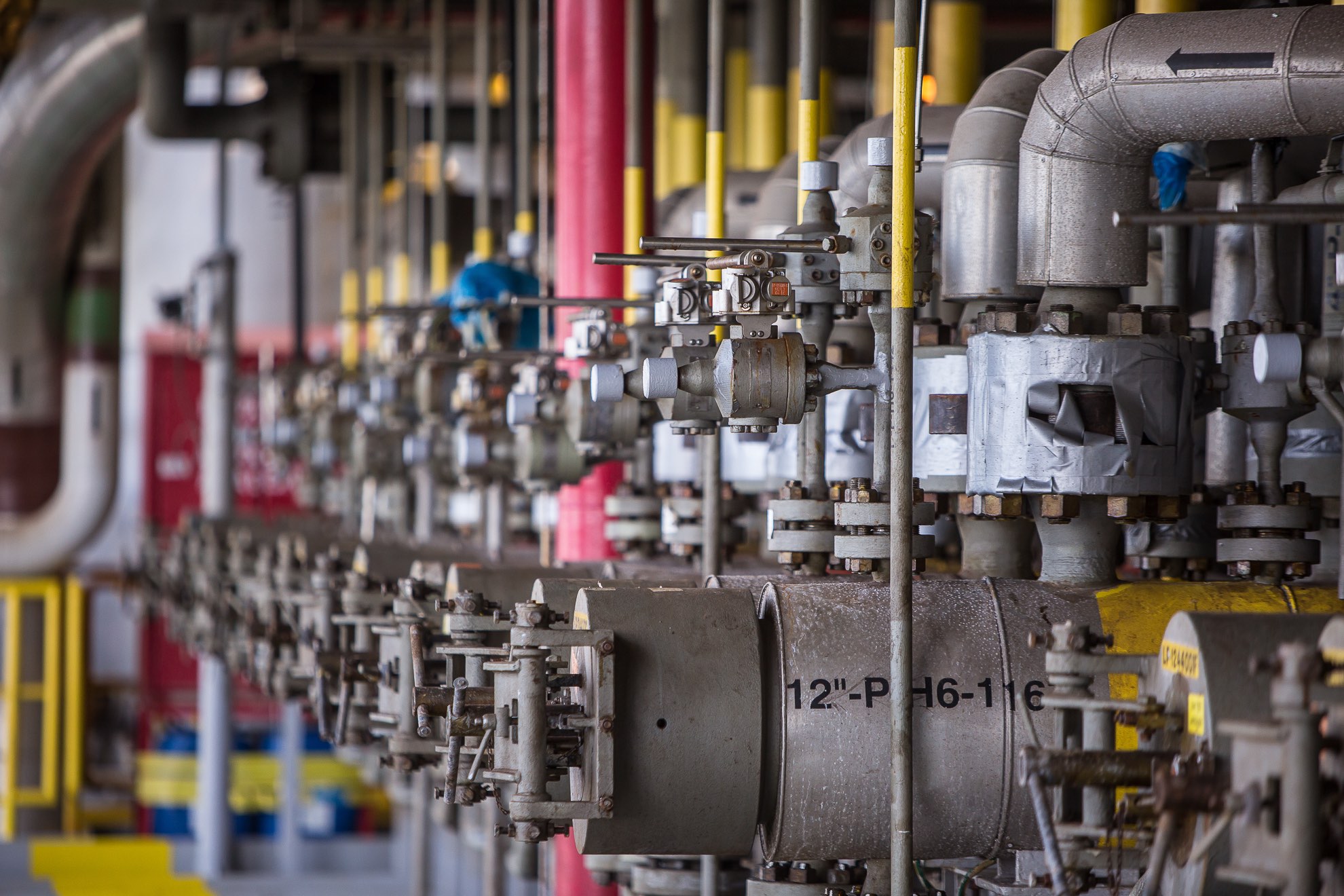

PIG Launchers and Receivers

PIG Launchers and Receivers

Water treatment and processing

Water treatment and processing

Offloading area

Offloading area

Laboratory module

Laboratory module

Automation and electrical

Automation and electrical

Helideck

Helideck

Accommodation module

Accommodation module

Flare Tower

Energy generation

PIG Launchers and Receivers

Water treatment and processing

Offloading area

Laboratory module

Automation and electrical

Helideck

Accommodation module

01

09

| Customer | Petrobras Netherlands BV |

| Scope of work | EPC |

Segment

Oil & Gas

The engineering and supply works were carried out in the city of Rio de Janeiro, while the manufacture, assembly and subsequent fitting of all the modules into the ship supplied by the customer were carried out at Techint E&C’s Offshore Unit in Pontal do Paraná, on the coast of the Brazilian state of Parana.

Driving energy development in Brazil

2014-2019

Start of work

August

2014

Heavy equipment assembly

Pieces of equipment weighing over 400 tons were installed. The biggest challenge involved lifting essential items, principally two oil treatment containers, which took approximately three months to cover the 470 km between the Bardela plant in San Pablo and Pontal do Paraná.

April

2015

Arrival of the FPSO P-76 ship from Rio de Janeiro

The vessel’s arrival meant that work to assemble the modules could move ahead, as well as the integration and fitting of all the different items on board.

July

2016

Start of module assembly

A total of 43 assembly operations were necessary, involving the company’s own cranes and the special Mammoet heavy lift crane, one of the largest of its kind, with a lifting capacity of up to 3,600 tons.

October

2016

Start of module integration

The maneuvers involved moving around 26,000 tons of machinery and equipment. This means that at the peak of construction work, there were 5,000 employees working on the site at the same time. Since work started in 2014, the project has created 9,000 jobs. January 2017

January

2017

Start of carry over

May

2017

Buoyancy tanks

60 submarine buoyancy tanks measuring over 3 meters high and weighing 14 tons were installed, essential for the task of extracting offshore oil by connecting the risers and cushioning the impact of sea currents.

July

2018

FPSO-P76 Sail away

The operation began at dawn and involved a dedicated team of professionals who worked hard to ensure the platform could sail out to sea and accomplish its mission. After this successful event, the P-76 traveled to the Santos Basin to be put into service at Bahia de Santos, on the Brazilian continental shelf.

December

2018

First gas injection

The P-76 conducted the first gas injection operation following three months of preparation. The platform has sufficient capacity to process 150 thousand barrels of oil and process 7 million m3 of natural gas.

May

2019

Udinson and Wellington Curta · in charge of Scaffolding at the P-76 project in Brazil

“We started out as construction helpers, working to assemble the scaffolding. Today, thanks to the opportunities the company gave us, and after putting in a lot of effort, we are proud to be in charge of the entire scaffolding area."

Munique Souza · Engineer P-76

"I joined Techint on an internship program, and ended up becoming the engineer responsible for the hydrojet inspection group in the project's Safety Department."

01

02

This site uses cookies. By using our website (through any device), you agree to the application of these rules on the use of cookies. You can access more information about these cookies in the Terms and Conditions.