Punta Negra Hydroelectric Dam

Contract signing

The Techint-Panedile consortium signed a contract with Energía Provincial Sociedad del Estado to carry out the Punta Negra project.

San Juan, Argentina

A major infrastructure project that contributed to improving the use of water resources in the province of San Juan

hectares of land benefited from the expansion of local irrigation capabilities.

GWh annual output.

of the province's electricity needs are supplied by Punta Negra and Los Caracoles.

Punta Negra Hydroelectric Dam

Contract signature and start of the project

of reinforced concrete

workers at peak construction

End date

contract amount

Contract signature and start of the project

of reinforced concrete

workers at peak construction

End date

contract amount

Intake

Intake

Spillway

Spillway

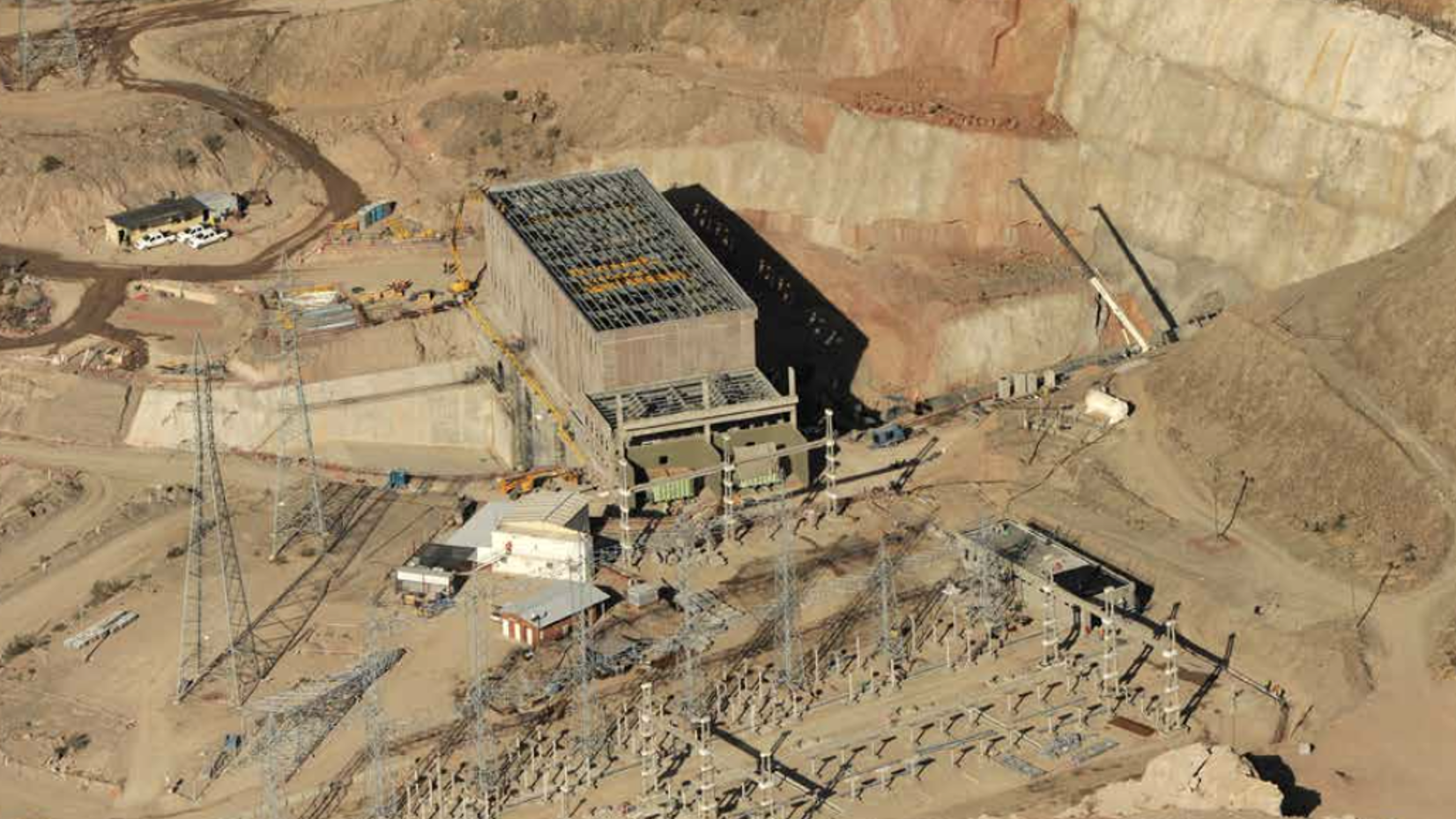

Powerhouse

Powerhouse

Substation

Substation

Bottom outlet

Bottom outlet

Dam

Dam

Reservoir

Reservoir

Intake

The intake works need to be capable of discharging enough water to meet downstream needs.

Spillway

This guarantees that reservoir water levels do not exceed the level of the crest of the dam in case of a rise in water levels or flooding in the San Juan river.

Powerhouse

This is the location for the turbines and generators which convert the energy produced by the stationary hydraulic jump first into mechanical energy and then into electricity.

Substation

Electricity is received from the powerhouse and sent to the high voltage line linking Los Caracoles and the city of San Juan.

Bottom outlet

This drains the reservoir under the level of the intake during maintenance or emergency operations.

Dam

Made of loose rock-fill with a concrete face, 118.40 m high and measuring 740 m along the crest.

Reservoir

Enables 500 Hm3 of water to be available for electricity generation and irrigation.

01

07

The intake works need to be capable of discharging enough water to meet downstream needs.

This guarantees that reservoir water levels do not exceed the level of the crest of the dam in case of a rise in water levels or flooding in the San Juan river.

This is the location for the turbines and generators which convert the energy produced by the stationary hydraulic jump first into mechanical energy and then into electricity.

Electricity is received from the powerhouse and sent to the high voltage line linking Los Caracoles and the city of San Juan.

This drains the reservoir under the level of the intake during maintenance or emergency operations.

Made of loose rock-fill with a concrete face, 118.40 m high and measuring 740 m along the crest.

Enables 500 Hm3 of water to be available for electricity generation and irrigation.

| Customer | Energía Provincial Sociedad del Estado (EPSE) |

| Scope of work | Detail engineering, supply management, comprehensive construction and commissioning |

Segment

Energy

Taking the lessons learned at Los Caracoles, we developed a plan to shorten the execution periods for the different works, reducing slab casting times by over 50 percent. This led to significant improvements in productivity in general and shortened construction deadlines

The province of San Juan is located in a semi-desert region in the northwest of Argentina. Its arid, irregular landforms stretch out from the foothills of the Andes to the Sierras Pampeanas, the structural relief running parallel to the Andes. Some 80% of the province is covered by rocky, mountainous terrain.

Province

Latitude

Longitude

Contract signing

The Techint-Panedile consortium signed a contract with Energía Provincial Sociedad del Estado to carry out the Punta Negra project.

November

2009

Intake works

The first issue to be resolved was the construction of the sluice gate, a 60-meter high inclined reinforced concrete tower supported by rock with three internal pipes, each housing a gate, cofferdam and ventilation system. A self-climbing core wall system was designed on site with a stripping system using scissor-type support arms.

>>

2009

Slab at height

A 90-centimeter-thick slab with cantilevered vertices had to be built on the operating platform, as conventional shoring was not feasible at 40 meters above ground. Two large precast beams were designed and built from which pre-stressed joists were set as the bottom of the self-supporting slab.

>>

2010

Spillway

Building the spillway was a complex assignment due to its size and the number of construction stages required for the massive concrete face that, in turn, needed hydraulic profiles requiring special finishing. The key challenge was the fact that there was only one access from the road along the left bank of the dam at the height of the crest.

>>

2010

Materials and logistics

Large cranes had to be located in three different positions with a radius of movement allowing them to cover the entire work area without interfering with each other’s movements. From this platform, more than 50,000 cubic meters of concrete were poured, and distribution pipes of up to 200 meters in length were laid in complex logistical conditions.

>>

Concrete face

One of the greatest challenges presented by the project concerned how the different construction stages were to dovetail with the filling of the dam itself. This process was affected by geological characteristics that were different from those foreseen on the left bank, and impacted on the programming of the execution stages.

>>

Intake works

The filling of the Punta Negra dam was completed

>>

2013

Intake works

The first issue to be resolved was the construction of the sluice gate, a 60-meter high inclined reinforced concrete tower supported by rock with three internal pipes each housing a gate, cofferdam and ventilation system. A self-climbing core wall system was designed on site with a stripping system using scissor-type support arms.

>>

This site uses cookies. By using our website (through any device), you agree to the application of these rules on the use of cookies. You can access more information about these cookies in the Terms and Conditions.